Monitor Sync Box

(11/6/2003).There are many very good quality workstation monitors being dumped, which with a little bit of effort make for very good PC monitors. I built the first box described here a few years back when I rescued a Sun 17" monitor from a skip (Photo 1). The best ones to get are multi-sync versions. Fixed sync monitors can be used, but they are not dealt with here.

Photo 1: Sync box with BNC connectors. Originally made (25/3/1998).

(Cast aluminium box for screening).

Only a few parts are needed for this project, and even some of those can be scrounged from other old equipment. (For example on the second monitor box shown below (Photos 2 & 3), I used the VGA lead from an old broken 14" monitor - it saved buying a VGA connector and screened cable).

Photos 2 & 3: Sync box without BNC connectors. Second box made (early 2002).

(Cast aluminium box for screening).

The minimum parts list is a small screened box, some verocard, some wire, a switch, a 74HC86 quad XOR logic chip, a 100nF ceramic capacitor, and optionally the parts for the LM317T power supply circuit.

Start by drilling all the necessary holes in the screened box, it is easier to plan this now and drill ALL the holes, rather than try and drill more later. Any cables entering the box should be protected at entry using a grommit or some other protective device and the cables should be anchored to the box to stop them from being yanked out of the box. I have previously used P clips (Photos 2 & 3), or proper cable clamps which bolt to the box.

With the Sun monitor cable you can either buy an expensive connector for it and mount this on the box, or to save costs, just cut the existing connector off and hard wire in to the box directly. (Dont throw the connector away - you can use it to work out which wires you need for which signals). The Red, Green and Blue signal coax cables should be directly joined in the box to the VGA lead matching signal colours, and try and keep as much of the cables screened as possible - this helps with the signal quality.

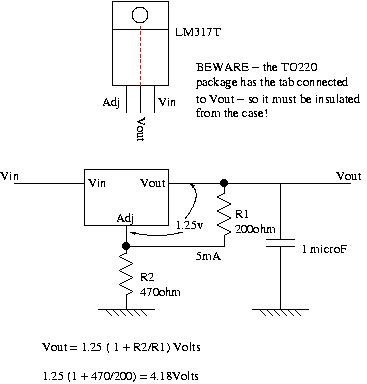

When building my first box, I tried to grab power for the XOR chip from the monitor lead itself - it results were not very successful, therefore I added the LM317T circuit given in Figure 1. Its input can be ~6 volts up to 30 volts - I personally stuck to lower voltage input. You could use a completely external supply if you want to, you need 4-5 Volts DC. Connect this to the power supply pins of the XOR chip. I would recommend using a chip socket for the chip rather than solder it directly to the verocard. Connect the 100nF ceramic capacitor directly accross the chip +v and ground connections.

Figure 1: Power supply circuit. Originally made (29/9/1999).

Connect the relevent wires from the Sun monitor (Pinout Figure 3) to the XOR output, one of the XOR inputs to the switch, and then the other XOR gate inputs to the VGA monitor lead (Pinout Figure 2). See Figure 4 for the XOR wiring connections. Inputs A and B are connected to HSync and VSync from the PC, output C is connected to CSync from the Sun monitor. The Sync ground connections should all be connected together. It is important that the unused XOR inputs are connected to ground and not left floating and unconnected.

HD15 pin out

|

Figure 2: HD15 Pin Out. |

Sun 13W3 pin out

|

Figure 3: 13W3 Pin Out. |

Figure 4: XOR/XNOR 74HC86 Circuit.

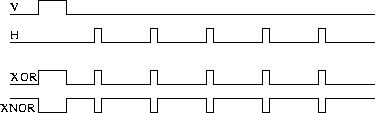

Figure 5: Waveform 1, +vsync +hsync.

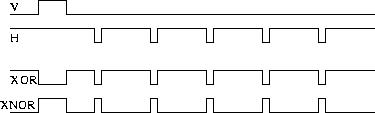

Figure 6: Waveform 2, +vsync -hsync.

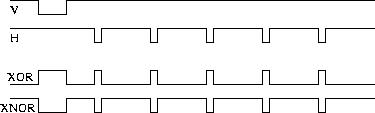

Figure 7: Waveform 3, -vsync +hsync.

Figure 8: Waveform 4, -vsync -hsync.

Any unused wires from both leads should be left unconnected and insulated individually. The overall cable screen from both signal leads should be connected together and also connected to the box for screening.

Several proposed circuits from other websites use an XOR and a NOT gate - this requires 2 chips, plus if you use the circuit below you can use the switch to change between XOR/XNOR therefore any polarity csync can be produced from any combination of input hsync/vsync polarity. This is shown in the waveforms from Figures 5-8.

That's it! Now check your connections, connect up to the PC and switch both the monitor and PC on. If the Sun monitor goes into 'Suspend' or 'active off' mode then probably one of the sync signals is the wrong polarity - just flick the switch and that should wake it up. Last recommendation - from the Sun manual - press the reset switch on the monitor front panel - this makes the monitor set itself up for the new signal levels you are supplying it (you will still have to set the picture size etc. on the screen, but this reset sorts outs the colours).

Enjoy!

Below are the Sun Monitor specs. from the official manual, plus some other useful links.

Sun Multisync GDM-17E10 Specifications (from manual)

- RGB 0.714V p-p (Using RGB 1.0V p-p may not give a good picture!)

- Maximum Horizontal resolution 1280 (I run mine to 1600 OK)

- Maximum Vertical resolution 1024 (I run mine to 1200 OK)

- Horizontal Sync range 30-82KHz

- Vertical Sync range 50-150Hz

- If H sync OR V sync are not present then the monitor goes in to 'Suspend mode'

- If BOTH H sync and V sync are not present then the monitor goes in to 'Active Off Mode'

- When supplying the monitor with new signal levels from a different machine it is worth pressing the reset button with the new signal present - the monitor then sets itself up for these new levels.

Links

- Use your old Workstation Monitors with Linux/XFree86 - With Linux you can use +/-vsync and +/-hsync in the XF86Config file. Other operating systems may not provide such control so the circuit above is more flexible.

- Notes on Video Conversion